Technical Study

[Case Study]Boosting Productivity and Safety Through Optimized Factory Comfort

In a demanding industrial environment, thermal comfort is far more than a luxury – it’s a fundamental driver of worker well-being, productivity, and operational efficiency. At TERAO, we recently partnered with a leading automotive manufacturer in Southeast Asia to transform their challenging production workspace into a cooler, safer, and more efficient environment. The Challenge: Overheating, Discomfort, and Inefficient Operations Our

[It’s official] DELTA GALIL VIETNAM Factory ACHIEVED LEED O+M GOLD CERTIFICATION WITH ENERGY OPTIMIZATION APPROACH.

Delta Galil Vietnam, an Israeli textile firm, operates a significant textile and garment factory in the Cat Trinh Industrial Cluster, Gia Lai, Vietnam. Established in 2015 with over 3,600 workers. Delta Galil Vietnam is known for supplying leading global fashion brands. This accomplishment underscores the company’s commitment to sustainable practices and responsible growth. The textile industry, like many manufacturing sectors,

Achieving Sustainability Goals Through Carbon, Energy and Water Audits

A leading global textile and consumer goods logistics group, committed to minimizing its environmental impact, embarked on a journey to aggressively reduce its carbon footprint. Aligned with the Science Based Targets initiative (SBTi) target, the group aimed to achieve a 42% reduction in Scope 1 and 2 greenhouse gas emissions by 2030, compared to a 2021 baseline. Recognizing the significant

Forvia Fengcheng Mega Plant – LEED v4 Gold: OneClick LCA case study

Forvia is a French global automotive supplier headquartered in Nanterre, France. They are an automotive technology group at the heart of smarter and more sustainable mobility, bringing together expertise in electronics, clean mobility, lighting, interiors, seating, and lifecycle solutions to drive change in the automotive industry. Forvia, through its two entities, Faurecia and Hella, has demonstrated over the years a

[Case study] A Feasibility Study on Sustainable Office Relocation

Building Fit-out and its Carbon Behaviour China’s ambitious target of achieving carbon neutrality by 2060 has significant implications for the building sector, which is responsible for nearly half of all global carbon emissions. Specifically, building operations account for 28% of these emissions while new construction contributes to 21%. In China, construction generates 21.6% of emissions, with 28% coming from new

[Expertise] Reducing the carbon footprint of your suppliers

Implementing a green supply chain is a strategic decision that offers various competitive advantages to a company. Firstly, a green supply chain can optimize resource management, reduce operational costs, and contribute to growth. This can be achieved by using recyclable raw materials, eco-friendly packaging, energy-efficient transport solutions, and manufacturing processes that limit water and electricity consumption. Secondly, many governments have

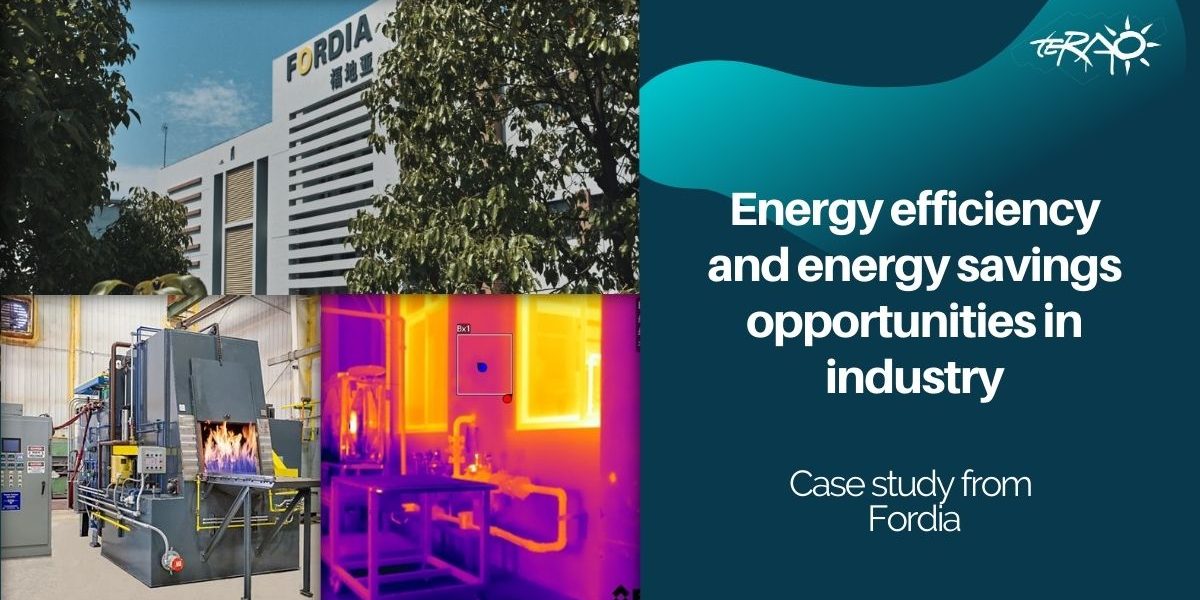

[Case study] Fordia – Energy efficiency and energy savings opportunities in the industry

[Case study] Fordia – Energy efficiency and energy savings opportunities in the industry Like many players in today’s society, industry stakeholders are taking concrete action to reduce energy consumption and reduce their impact on climate change. Fordia is focusing on drastically reducing its global carbon emissions and has launched a global Energy Efficiency program on all of its operations combined

[Case study] Life Cycle Assessment: Logistic assets across China

Case study – Life cycle analysis: Logistics assets across China TERAO was asked to carry out a Life cycle analysis at an early stage of 5 new projects located in China (5 logistics buildings). The goal was to create a baseline based on existing projects and help set up a carbon reduction target for the client. The assessment included the construction

Our clients recommend us: Dominique Laloux, vice-chairman of ERLAB in China, about their new factory in Kunshan

At TERAO, we have the expertise to give advice on the design of a building. What for? To optimize energy consumption while being comfortable for its occupants. It is particularly vital in an industrial asset, where production lines could generate a lot of heat, and where comfort is at stake for the workers. One of our clients had this issue

How TERAO can solve your energy issue? – Cold rack case study

How TERAO can help you to efficiently cool your industrial rack? Case study – Cooling system optimization TERAO’s team worked as energy efficiency specialists to optimize the cooling system for a specific case. A Taiwan based client whose process is highly impacted by the weather needed to control well humidity and heat by adding new cooling racks inside a warehouse. The

Durability of materials – How to anticipate future damages of materials?

The durability of materials is a strategic methodology to design for robustness and resilience, firstly to ensure and maintain an esthetic aspect of building, and secondly to avoid the high cost generated by material replacement. Every material or product has its own life expectancy, the defined use of these products should be in line with their life expectancy. Meanwhile, their

Functional adaptability – How to anticipate the building future needs?

Functional adaptability is the concept behind the constant evolution of building needs during the operational phase. Indeed, it is very important to anticipate all of these challenges related to new uses of the building, maintenance and repair work. All of these changes have most of the time the potential to solve functional problems and to provide improvements by considering the

Life Cycle Analysis – How to assess the potential environmental aspect of a product?

The Life Cycle Assessment approach has been used since 1970. First of all, in the context of Oil-Shock, it was used by the industry to link the production and transportation of products to the energy cost. Then the focus grew to the environmental impacts of activities since 1990. The approach is now standardized by ISO 14 040 and ISO 14

Life Cycle Cost Analysis – How to understand, predict and reduce building operational costs

Life Cycle Cost Analysis In a construction project, the financial assessment is mainly based on initial capital costs. However, the costs generated during the asset operation period can be significant and are often neglected during the design and development stage. Furthermore, these costs, especially maintenance and replacement costs are highly related to the choices made during the design stage. Therefore,

![[Case Study]Boosting Productivity and Safety Through Optimized Factory Comfort](https://teraoasia.com/wp-content/uploads/2025/09/Cover-photo-150x150.png)

Recent Comments