Last Tuesday 6th April, in Changzhou, was held “The Sustainable Factory – seminar & panel discussion” by the European Chamber of Commerce in China, at SOPREMA Changzhou factory. The concern around sustainability is growing among governments, corporations and civil society, and it applies to factories.

The event was held at SOPREMA Changzhou factory (credits: SOPREMA)

Manuel Ramos, GM of TERAO Asia, introduced trends for factories to get more into sustainability such as stricter regulations and verification by authorities, higher operation cost, CSR guidelines pressure or high turnover of qualified workers. Therefore, as he stated, pressure is increasing on industrial players.

“More and more factories will need to comply with local regulations or corporate guidelines for a more sustainable and comfortable factory.”

Gaspard and Maxime intervention at EUCCC event in Changzhou

During this event, the different speakers shared different strategies how to make it.

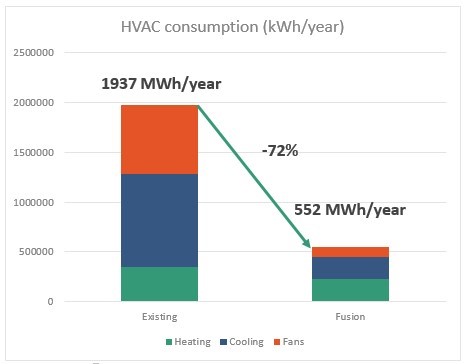

Factories can use less energy, less water and emit less carbon emissions: our Business Development Manager Gaspard Lemoine-Scelles introduced TERAO different case studies of energy optimization in factories followed by an introduction of carbon footprint methodology, for existing factories.

“Especially for existing factories, the potential for energy savings can be huge, and it will help to reduce factories carbon footprint along this process. Each factory has its specificities: energy audits and carbon footprint assessment can help towards identifying each factory potential improvements and shaping an action plan.”

Scopes 1, 2, 3 of carbon footprint assessment

Our Operation Manager at TERAO Maxime Besseas focused on energy efficiency and water efficiency for new constructions, as in China, new factories are still booming:

“Often, factories consumption could be lowered easily by a minimum of 30%, through design adjustment. For instance, by adjusting the need for HVAC systems to the right usage and the right sizing, high-efficiency technologies, robust technologies such as VFD. When adjustments are done during design stage, it will help save money compared to corrections happening during post-construction.”

“Green Building certifications such as LEED, BREEAM, GBL can help to drive the sustainability target of the client in a clear manner with guidance. You can find the same to enhance well-being of employees, through the WELL certification.”

Building Envelope has a key impact on the abovementioned aspects. Olivier Brault from SOPREMA showed examples of how to reduce energy usage and reduce carbon footprint through an optimized design and material choice for the building envelope.

To reduce the impact of the factory, not only do you need optimized factory design, equipment and materials, but a smooth operation and maintenance process is also crucial. It will help to enhance the lifetime of assets and better control the performance of the overall factory. Bruno Lhopiteau from SIVECO explained and introduced this idea with SIVECO solution around smart CMMS (Computerized Maintenance Management system) system.

Rethinking factory structure and interior design is of the utmost importance to make it more comfortable and sustainable, as Romain Poirier from French House suggests. Solutions such as bicycle storage or facilities, better choice of material, lighting design, etc. will help to improve the comfort, safety of the employees as well as sustainable features of the factory.

Regarding noise pollution, Jean-Philippe from Delhom Acoustique shared how this issue could be tackled easily and smartly, through acoustic studies and solutions, during Design (less costly) or also for existing factories. It will help to reduce environmental impact of the factory on the neighborhood, as well as improve comfort of the employees.

If you need any information about sustainable solutions in the industry and how to make your factory more healthy and sustainable, please do not hesitate to contact us at glemsce@teraochina.cn. TERAO would be happy to help you optimize your asset through the different mentioned aspects.

Explore more:

![[Expertise] How to conduct an energy audit to identify areas of energy waste in business](https://teraoasia.com/wp-content/uploads/2024/06/Expertise-1-150x150.jpg)

Leave A Comment