Last Thursday 12th November, in Taicang, was held “The Sustainable Factory” seminar by the German Chamber of Commerce in China. The concern around sustainability is growing among governments, corporations and civil society, and it applies to factories.

Manuel Ramos, GM of TERAO Asia, introduced the topic by reminding the ambitious carbon neutrality goals set by China & Europe, respectively by 2060 and 2050. Therefore, as he stated, pressure is increasing on industrial players.

“More and more factories will need to comply with local regulations or corporate guidelines for a more sustainable factory. Action Plans need to be set up now at the local level on a broad range of Sustainability topics”

During this event, the different speakers shared how companies can start making their facilities more sustainable and how it can bring real economic value and social benefits.

Tommaso Colli from PHC Advisory and Mandy Du from D’Andrea and Partners Legal Counsel reminded different laws in China around environmental protection, especially the “Environmental Protection Tax Law of China” 《环境保护税收法律》, giving a framework on tax to be paid when factories discharge pollutants in air, water or waste; they also shared about laws around COVID-19 and Environmental protection related to Epidemic prevention 《关于统筹做好疫情防控和经济社会发展生态环保工作的指导意见》。

Apart from tangible pollutants, factories can also be great sources of noise pollution, for the surrounding environment or the workers. Jean-Philippe Delhom from DelhomAcoustics reminded us how China has become more stringent regarding the noise impact from industrial sites, through different regulations, such as GB 12348-2008 “Emission standard for industry enterprises noise at the boundary”《工业企业厂界噪声排放标准》or GB/T 50087-2013 “Design of noise control of industrial enterprises” 《工业企业噪声控制设计》. He shared how this could be tackled easily and smartly, through acoustic studies and solutions, during Design (less costly) or when an existing building encounters this issue.

Those solutions could be implemented as Tom Bus from Maars Living Walls showed. He not only shared how their products helped to tackle noise issues in office space in factories but also air quality issues. It helped to improve the comfort of the employees as shown in the different case studies.

Yes, factories can be comfortable and sustainable, meaning using less energy, less water and emitting less carbon emissions. Our Operation Manager at TERAO Maxime Besseas showed different examples of how to reach these goals, focusing on energy efficiency and water efficiency:

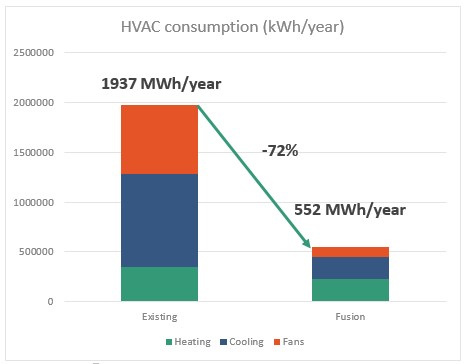

“Often, factories consumption could be lowered easily by a minimum of 30%, through design adjustment. For instance, by adjusting the need for HVAC (Heating, Ventilation and Air-Conditioning) systems to the right usage and the right sizing, or by decreasing the unnecessary external heat gains created by unnecessary glazing; by using high efficiency technologies such as Heat pumps or Fusion AHU, adapting to each project, or using robust technologies and operation measures such as Variable Frequency Drives or Heat recovery / Free Cooling. When adjustments are done during the design stage, it will help save money compared to corrections happening during post-construction.”

Energy efficiency can reduce energy consumption and carbon emissions

“Green Building certifications such as LEED, BREEAM, GBL can help to drive the sustainability target of the client clearly with guidance. You can find the same to enhance the well-being of employees, through the WELL certification.”

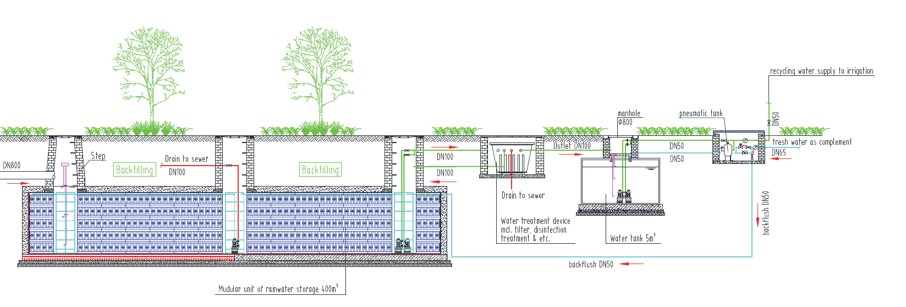

“Regarding water, in regulations, there are “3 red lines” for water efficiency and industries must reduce consumption from 2010 levels by -35% by 2020, and by -60% by 2030. One solution is rainwater collection to save water.”

Last but not least, after reducing energy usage, carbon footprint can be decreased even more by installing Solar PV panels on the site or roof of the asset and implementing PPA (Power Purchase Agreement), as suggested by Hally Huang from Symbior Solar, if local regulations and measures can be favorable.

Other suggestions in the field of Energy savings, Water consumption reduction, Health and Comfort (acoustic, air quality), Renewable and alternative energies and Smart monitoring were mentioned by our speakers. These are all typical solutions TERAO has suggested to customers in the past and present.

If you need any information about sustainable solutions in the industry and how to make your factory more healthy and sustainable, please do not hesitate to contact us at glemsce@teraochina.cn. TERAO would be happy to help you optimize your asset through the different mentioned aspects.

Explore more:

![[Expertise] How to conduct an energy audit to identify areas of energy waste in business](https://teraoasia.com/wp-content/uploads/2024/06/Expertise-1-150x150.jpg)

Leave A Comment