Energy modeling is a whole-building simulation process that engineers, architects, and researchers use to model the energy consumption of heating, cooling, ventilation, lighting, electronic equipment, and process loads.

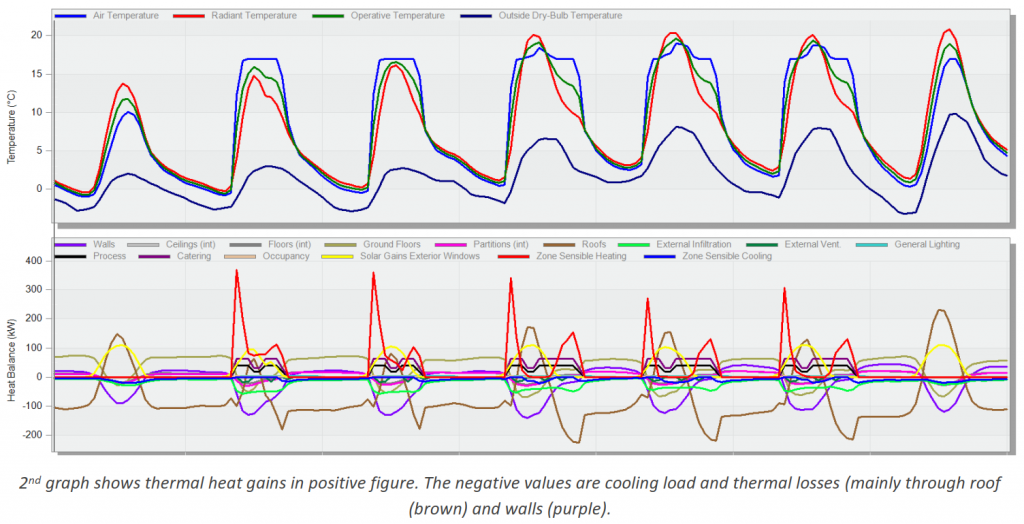

The simulation can give hourly time step results or even sub-hourly time step results (for example, 15 minutes) which makes it possible to carry out a detailed analysis of the thermal behavior of a building.

Passive design – Heat balance analysis

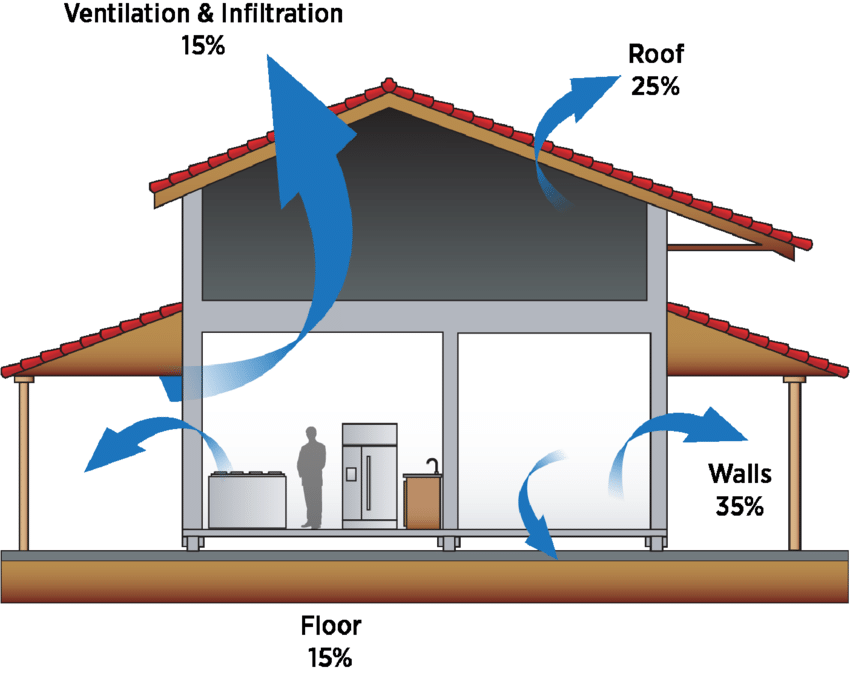

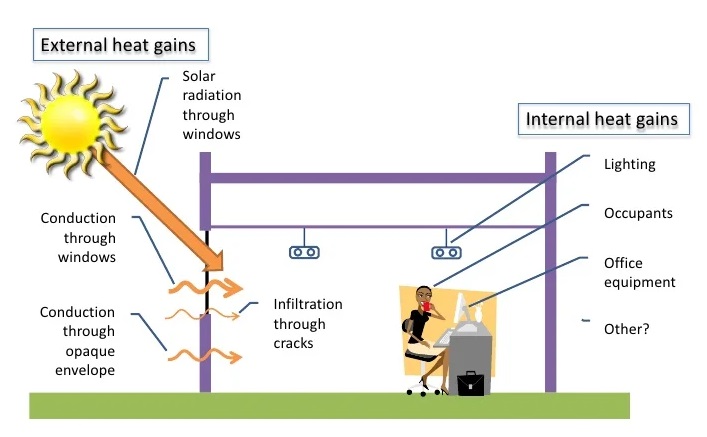

Energy modeling is the main tool to be used to understand the heat balance of a building and how each factor affects heating/cooling consumption and thermal comfort. The so-called heat balance is defined as the heat gains and heat losses in the building and is calculated throughout the year in the energy model.

The main factors that affect the heat balance are the input of the software and should be analyzed to reduce heating and cooling loads:

- Building envelope: heat gains/losses through the ground floor, external walls, roofs, and windows,

- External infiltration: the amount of outdoor air flowing into the building through air leakages,

- Solar gains via direct and diffuse sunlight,

- Occupancy via sensible and latent gains,

- Lighting,

- Electronic equipment loads and process loads

In the process of assessing a new construction or an existing building via energy modeling, the analysis of the heat balance is key to improving the passive design. Potential improvements can be, for example, U-value, Solar Heat Gain Coefficient of glazing, the color of materials, window-to-wall ratio, the orientation of glazing, sunshade, infiltration, etc.

Energy efficiency through energy modeling

Energy modeling can be used to determine the best energy savings option, the best cost-saving options, and the best carbon reduction options. Often, the best energy-saving option will yield the best carbon reduction and cost savings.

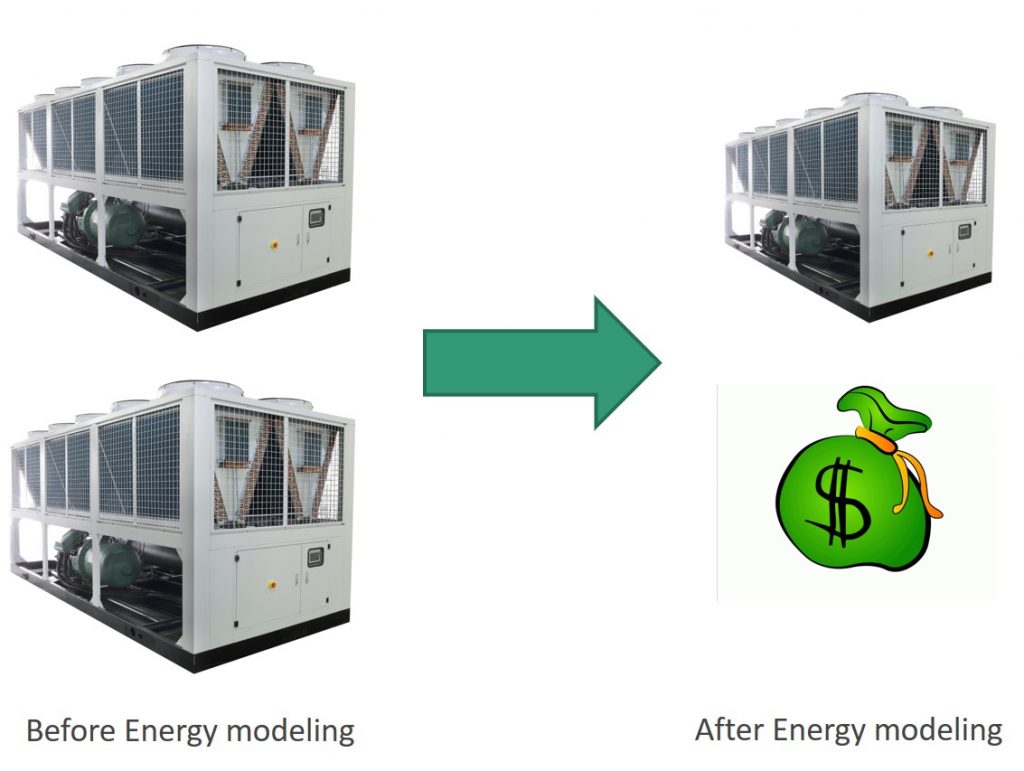

Right-sizing and detailed HVAC modeling

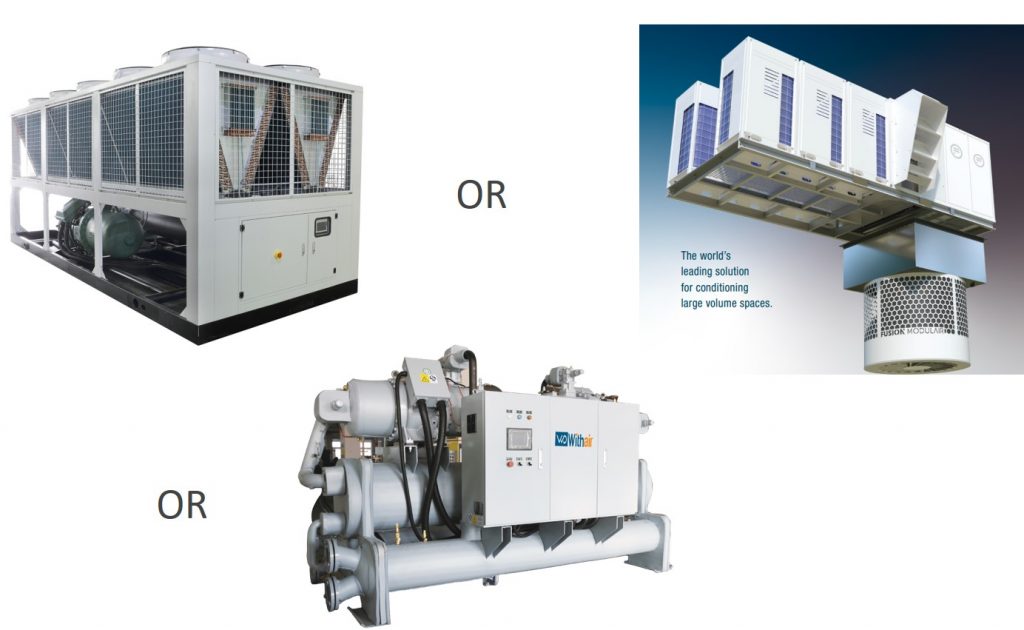

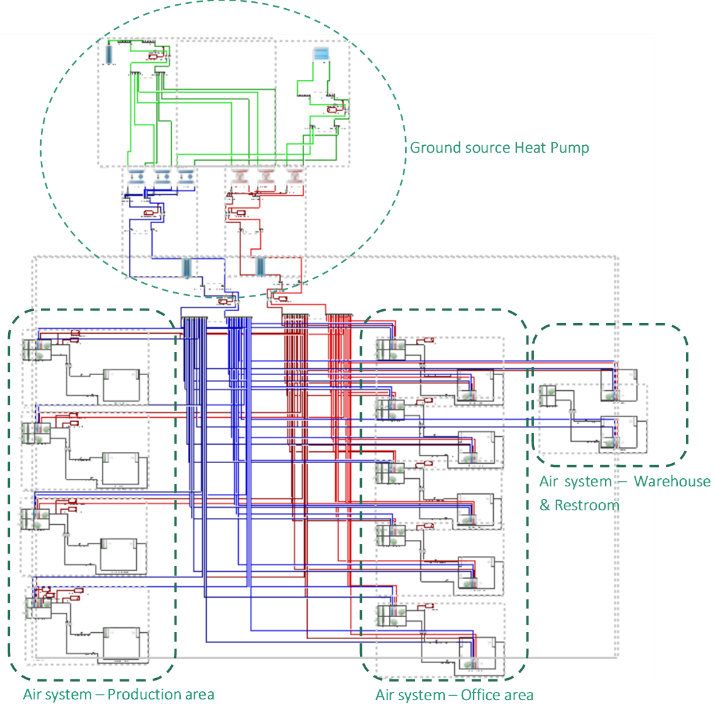

As most energy modeling software includes the possibility to model HVAC systems in detail, it is possible to use it as a tool to verify and validate the sizing of heating and cooling systems. The benefit of energy modeling in terms of sizing is to have a dynamic simulation that takes into account the variation of weather, occupancy, lighting, and plug load in the sizing process.

As an example, energy modeling can be used to validate the sizing of a central cooling/heating production system such as a Chiller, a Ground Source Heat Pump, or an Air Source Heat Pump or to validate the sizing of any interior heating/cooling unit such as Fan coil unit, VRV systems, etc.

HVAC regulation in energy modeling

HVAC regulation could be assessed through energy modeling to have a better understanding of which regulation is the most suitable to reduce energy consumption and improve thermal comfort. Regulation optimization examples could be temperature setpoints, schedules, humidity control, free cooling, etc.

Over the years, TERAO has developed strong expertise in energy modeling and has applied it to various types of projects and different climates. It could help some projects to reduce their energy costs by 30%.

Here is some feedback from our customers who hired us for our energy modeling services:

- Fordia energy optimization through

- Erlab energy optimization and cost optimization at the design stage through energy modeling

If you need energy modeling expertise for your project, you can contact our BD manager, Gaspard at glemoinescelles@teraoasia.com. We would be glad to accompany you to calculate the energy consumption of your project and to assist you in finding solutions to reduce energy consumption, carbon emissions, and/or energy bills.

Leave A Comment