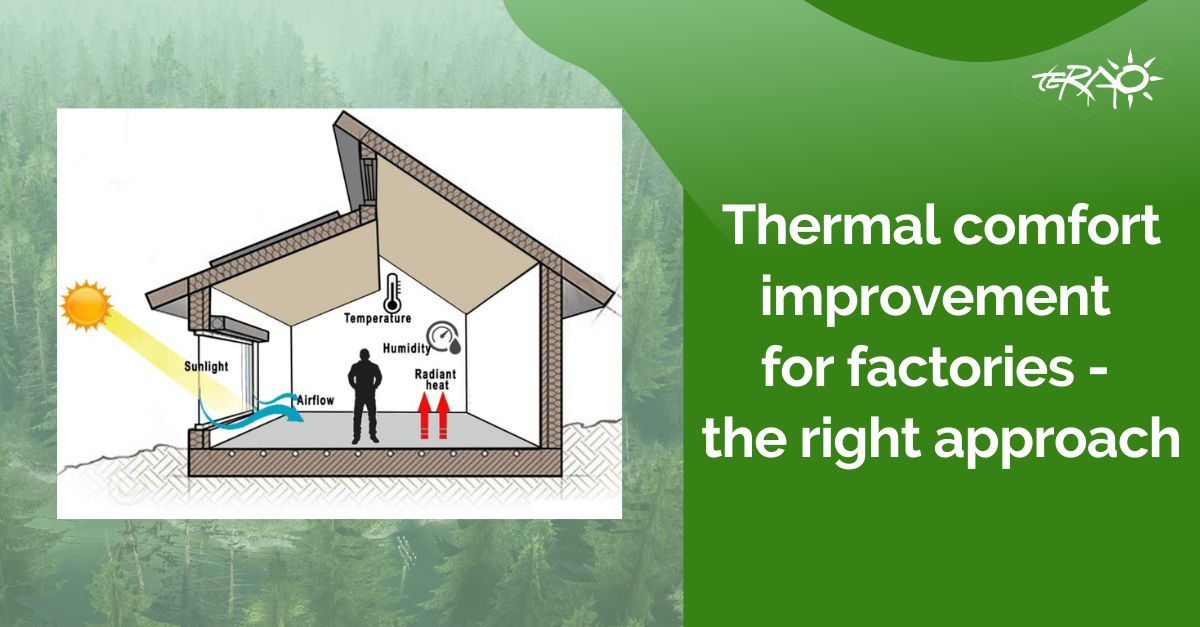

Thermal comfort in factories plays a pivotal role in ensuring a productive and healthy working environment for employees. Maintaining optimal temperatures and humidity levels not only enhances productivity but also fosters employee satisfaction and well-being. As industrial operations continue to evolve, adopting the right approach to ensure thermal comfort in factories becomes crucial. This operation needs to be done while prioritizing energy-efficient and low-carbon solutions.

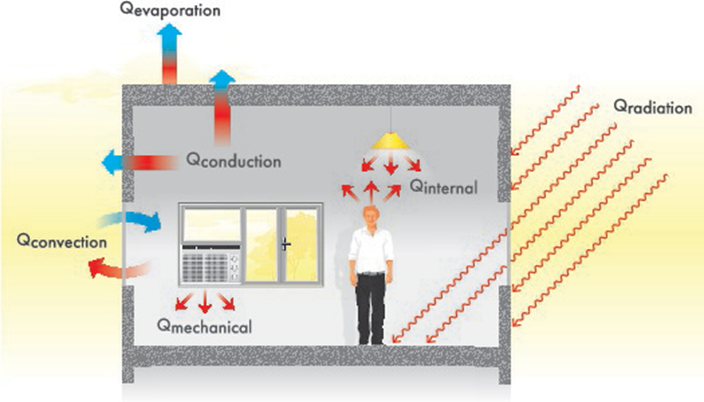

Thermal comfort optimization requires a systematic and multidimensional approach. It involves careful consideration of various factors, including temperature, humidity, air movement, and personal factors. The typical approach can be summarized in 3 steps:

- Assessment of the current Conditions: Conducting an initial assessment to understand the existing thermal conditions in the factory is vital. This evaluation involves analyzing temperature variations, humidity levels, airflow patterns, and identifying potential sources of discomfort. It can be done by creating a numeric model of the factory combined with on-site visits and data collection.

- Understanding Employee Requirements: Recognizing that everyone has different thermal preferences is essential. Gathering employee feedback through surveys, interviews, and observations helps understand their needs and expectations regarding thermal comfort.

- Analyzing Thermal Loads: Analyzing the thermal loads generated by machinery, equipment, and processes is critical. This assessment helps in identifying heat sources, their distribution, and their impact on the overall thermal environment.

This methodology helps to direct our research into the most critical sources of discomfort. Simulation tools such as thermal modeling or computational fluid dynamics can be used to understand the behavior of the building regarding the climate, the HVAC system and process loads very precisely and see the impact of each change on the thermal comfort.

This first analysis will highlight the main sources of heat, the most common in factories will be for example process heat load, building envelope, glazing, and air treatment systems. Focusing the solution investigation on these topics plays a vital role in minimizing energy loss and maintaining a stable indoor temperature.

Implementing the appropriate strategies for improving thermal comfort in factories can yield numerous benefits: TERAO’s aim is to balance the improvement of the well-being of employees with the implementation of energy-efficient solutions and sustainable practices. The potential results and solutions then include:

- Enhanced employee well-being: optimal thermal conditions significantly contribute to the reduction of fatigue, stress, and heat-related illnesses.

- Air quality improvement: addressing thermal comfort concerns often leads to improved air quality. Efficient ventilation systems not only regulate temperature but also remove pollutants and ensure a constant supply of fresh air.

- Energy efficiency: reducing energy consumption by using smart control systems, energy-efficient HVAC equipment, and optimizing the use of natural ventilation when possible. For example, solutions such as Evaporative cooling, white roof membranes, HVLS (High Volume Low-Speed fans), and solar film can be implemented.

Figure 1 – White roof membrane

Figure 2 – HVLS fans

- Sustainable practices: Thermal comfort studies also help the factory align with sustainability goals, reducing the carbon footprint while maintaining a comfortable workplace.

Monitoring and maintenance are essential to maintain the desired comfort levels over the long term. Conducting regular assessments, adjusting controls, and addressing any issues promptly ensures long-term effectiveness.

Written by Ugoline LAUTEL

Explore more:

- Sustainability and well-being in workplaces.

- How to optimize building with CFD

- Heat waves part 1

- Heat waves part 2

If you are interested in thermal comfort improvement for factories, we would be happy to assist you. Please feel free to contact our Business Development Director Gaspard at glemoinescelles@teraoasia.com for further information. We are committed to helping our clients achieve their sustainability goals and would be pleased to accompany you on this journey toward a more sustainable future.

One Comment

It’s clear that you are passionate about making a positive impact and your blog is a testament to that Thank you for all that you do