The global construction industry is at a crossroads. For years, the gold standard of “green building” was defined by operational efficiency—how much electricity a building consumes once the tenants move in. However, as our power grids become greener and HVAC systems more efficient, a new challenge has emerged from the shadows.

It is the “Elephant in the Room”: Embodied Carbon.

At TERAO, we believe that achieving true Net-Zero requires looking beyond the light switch. To build for the future, we must address the carbon that is “locked in” before a building even opens its doors.

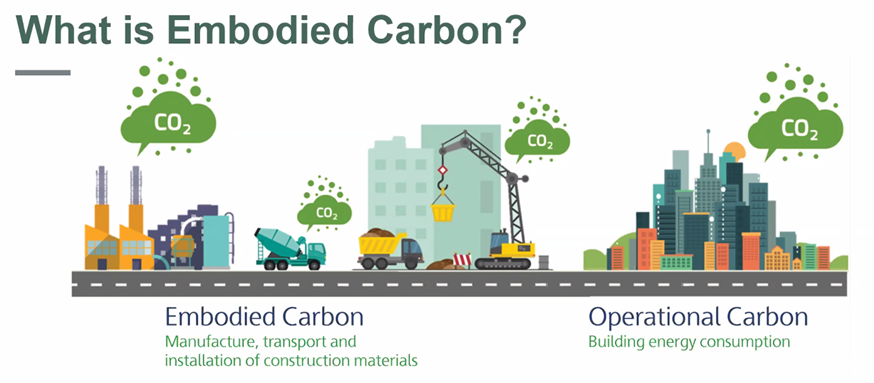

What is Embodied Carbon?

While operational carbon comes from heating, cooling, and power, embodied carbon refers to the greenhouse gas emissions arising from the entire life cycle of building materials. This includes:

- Extraction of raw materials (mining iron ore or quarrying stone).

- Manufacturing (the high-heat processes of kilning cement or smelting steel).

- Transportation to the construction site.

- Construction installation and eventual demolition/disposal.

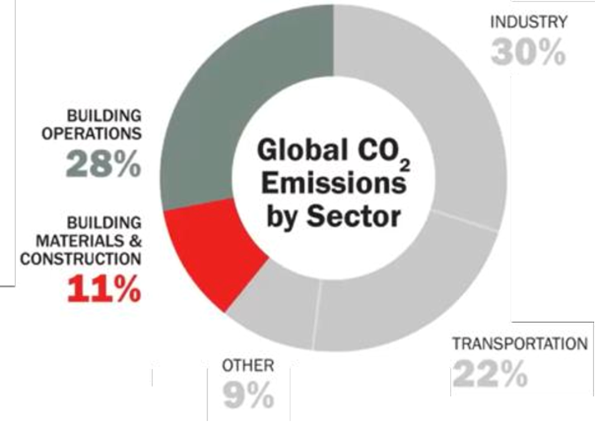

According to the World Green Building Council, embodied carbon is responsible for roughly 11% of all global carbon emissions. Unlike operational carbon, which can be improved over time with retrofits or renewable energy, embodied carbon is irreversible once the building is complete.

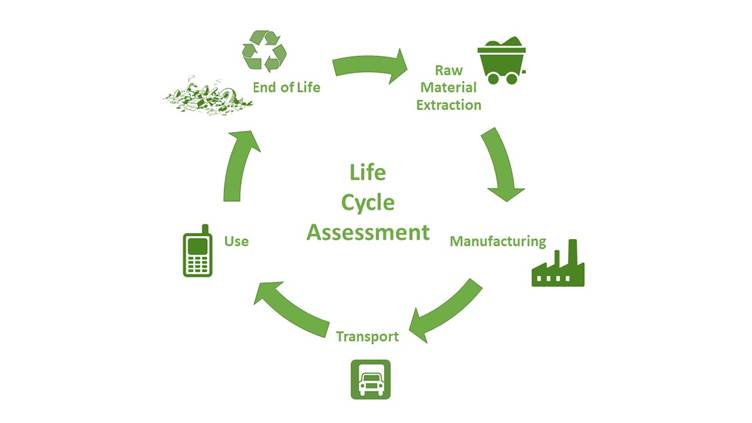

The LCA Advantage: Data-Driven Decarbonization

How to solve an invisible problem? At TERAO, the answer lies in Life Cycle Assessment (LCA).

LCA is a methodology used to compile and evaluate the environmental inputs and outputs of a building project. By performing an LCA during the preliminary design phase, TERAO allows developers to visualize the “carbon cost” of their architectural choices in real-time.

Cutting 15-25% of Carbon Before Breaking Ground

Our data shows that early intervention is the most cost-effective way to decarbonize. By using LCA to optimize material selection, TERAO typically helps clients reduce their project’s embodied carbon by 15% to 25%.

This is achieved through a three-pillar approach:

- Material Substitution: Replacing traditional cement with fly ash or slag blends, or opting for sustainably sourced timber instead of carbon-heavy steel when feasible.

- Structural Optimization: Working with engineers to reduce the sheer volume of materials needed without compromising safety.

- Circular Economy Thinking: Prioritizing materials with high recycled content or those designed for easy disassembly and reuse.

Bioclimatic Design: The Natural Force Multiplier

At TERAO, we don’t view LCA in a vacuum. We integrate it with Bioclimatic Design. By understanding the local climate – sun paths, wind patterns, and humidity – we design building envelopes that naturally regulate temperature.

This creates a “double win” for the environment:

- Lower Embodied Carbon: Fewer mechanical systems and heavy infrastructure are needed.

- Lower Operational Carbon: The building requires less energy to stay comfortable throughout its lifespan.

Why Now? The Business Case for Low-Carbon Construction

Addressing embodied carbon is no longer just a “nice-to-have” for CSR reports. It is becoming a core business requirement driven by:

- Regulatory Pressure: Governments worldwide are beginning to mandate embodied carbon reporting in building regulations.

- Green Certifications: High-level ratings in LEED, BREEAM, and HQE now heavily weigh LCA and material transparency.

- Investor Demand: ESG-conscious investors are carefully considering “Carbon Risk.” Buildings with high embodied carbon are increasingly seen as “trapped assets” that may lose value as carbon taxes rise.

The path to a Net-Zero future is paved with more than just solar panels. It is paved with low-carbon concrete, recycled steel, and intelligent, data-backed design.

The “Carbon Imperative” is clear: we must take responsibility for the emissions generated during construction. Through Life Cycle Assessment and Bioclimatic Design, TERAO provides the roadmap for developers to reduce their environmental impact while enhancing the long-term value of their assets.

Your new building’s carbon story is written before Day 1. Let’s make sure it’s a story of innovation and sustainability.

Explore more:

[Expertise] How to certify a carbon neutral building

[Case study] Forvia Fengcheng Mega Plant LEED v4 Gold – OneClick LCA

Leave A Comment