Delta Galil Vietnam, an Israeli textile firm, operates a significant textile and garment factory in the Cat Trinh Industrial Cluster, Gia Lai, Vietnam. Established in 2015 with over 3,600 workers. Delta Galil Vietnam is known for supplying leading global fashion brands. This accomplishment underscores the company’s commitment to sustainable practices and responsible growth.

The textile industry, like many manufacturing sectors, faces the challenges of balancing production demands with environmental responsibility. This manufacturer recognized the importance of integrating sustainability into its core operations and chose LEED certification as a comprehensive framework to guide and validate its efforts. The factory comprises two main buildings, totalling approximately 49,000 sqm, aimed at minimizing its environmental footprint while maximizing operational efficiency and enhancing employee well-being.

Before engaging TERAO, Delta Galil Vietnam faced the complex task of systematically identifying, implementing, and validating comprehensive environmental improvements across a large-scale manufacturing facility. They needed expert guidance to navigate the complex LEED certification process, identify areas for significant energy and waste reduction, and optimize indoor environmental quality for their large workforce while maintaining peak production efficiency. This is where the strategic partnership with TERAO began.

Delta Galil Vietnam Factory

LEED O+M Gold Certification

Major sustainable solutions implemented by Delta Galil Vietnam in partnership with TERAO

Delta Galil Vietnam has implemented a range of impressive sustainable solutions, demonstrating a comprehensive approach to environmental responsibility. Let’s have a closer look at the sustainable features of the factory:

Energy Efficiency: Smarter Operations, Significant Savings

Delta Galil Vietnam prioritizes energy reduction through investment in efficient technologies and practices. By applying Energy Audit Level 2 methodology, the identified energy efficiency recommendations led to a total energy reduction of 11.4% with an overall Payback period of less than 3 years. Notably, many existing systems were retrofitted or modified to achieve 9.3% energy saving without major replacement. For example, existing chillers were upgraded with variable frequency drives, resulting in a 15% reduction in chiller energy consumption.

The facility uses both electricity and biomass energy. Many cost-effective Energy Conservation Measures (ECMs) have been identified and implemented, particularly in important utility and facility systems such as vacuum pumps, biomass boilers (using Rice husk to produce heat energy for manufacturing purposes), compressed air systems, and chilled water systems.

Rice husk

Waste Management: Embracing Circularity

The facility has achieved a remarkable diversion rate for waste, preventing a significant volume of materials from ending up in landfills or incinerators. This achievement demonstrates a strong commitment to circular economy principles and highlights the potential for industrial waste management to contribute to a more sustainable future. For instance, textile scraps are recycled into new products, and organic waste is composted for use in landscaping. This focus on waste reduction benefits the environment and can lead to cost savings through resource recovery and optimized waste management processes.

Indoor Environmental Quality: Prioritizing Employee Well-being

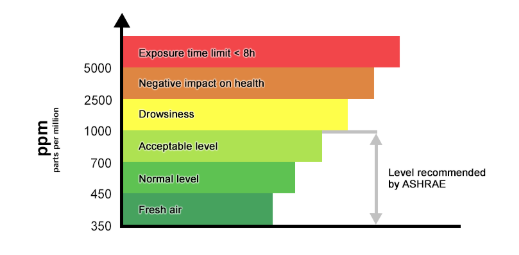

The facility prioritizes workers’ well-being by providing fresh air under ASHRAE 62.1-2010. Following implementation, an employee satisfaction survey revealed that most employees were satisfied with the building’s performance.

Furthermore, CO2 concentration tests consistently showed high air-quality levels, even in the worst-case scenarios, confirming the effectiveness of the project’s air quality management strategies. This commitment to healthy indoor environments directly results in a more productive and satisfied workforce.

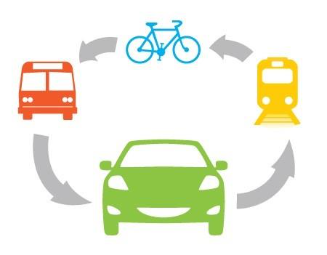

Location and Transportation: Reduce Carbon Footprint from Commuting

The strategic location of the factory in Binh Dinh province played an important role in the sustainability of the project. Approximately, most workers use low-carbon transport to commute to work, significantly reducing the project’s transport-related carbon emissions. This is achieved through company-provided shuttle buses and convenient bicycle parking facilities, promoting a culture of sustainable commuting.

These initiatives highlight Delta Galil Vietnam’s strong commitment to reducing its environmental impact and promoting sustainability in its operations. This LEED Gold certification is a testament to their dedication and a model for other industrial facilities.

Partner with TERAO: Your Guide to Sustainable Industrial

TERAO provides comprehensive LEED consulting services, guiding the manufacturer through the certification process and ensuring that all requirements are met with precision. We specialize in optimizing the sustainable performance of complex industrial manufacturing facilities. Our case study portfolio demonstrates our commitment to delivering impactful results (see portfolio on the website https://teraoasia.com/portfolio/)

At TERAO, we understand the challenges and opportunities associated with sustainable manufacturing. We work closely with our clients to develop suitable solutions that meet their specific needs and ambitious goals. Whether you are seeking LEED certification to reduce your environmental impact or looking to improve operational efficiency, TERAO can help you achieve your sustainability goals. Contact Mr. Gaspard – Business Development Director at glemoinescelles@teraoasia.com to learn more about how we can help you create a more sustainable future.

Leave A Comment